Document Type : Research Paper

Authors

1 University of Technology-Iraq

2 Mechanical Engineering Department, University of Technology, Baghdad-Iraq

Abstract

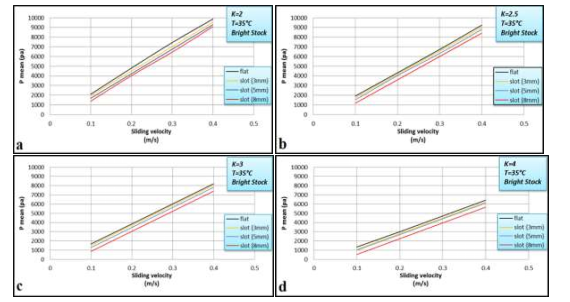

This research aims to study the effect of rectangular grooves on the lubrication mechanism in an inclined slider bearing. Reynolds' equation was used in the theory part to calculate the pressure gradient in a one-dimensional fluid film. The tilted sliding bearing compared the practical results, where the researcher manufactured and developed the device by adding pressure sensors along with the pad. These sensors will give accurate readings because they will read the pressure directly from the bottom of the pads without manometer tubes. Four pads were manufactured, one without grooves and three with rectangular grooves, varying slot widths (3, 5, 8mm), and a depth of 2mm. This study examined various variables: sliding velocities, pad inclination values, and oil temperatures. The conclusions indicated that the flat model is significantly superior to the groove’s models. One significant finding for grooved models is that as the inclination increases, the maximum load capacity approaches the pad's center, allowing grooved models to be used in applications requiring less load and weight. The maximum load-carrying capacity of flat and grooved models was in the film ratio (K) = 2–2.5. In contrast, the load capacity of the flat model was greater than that of the groove model by percentages of 0.5%, 4.27%, and 14.66%, respectively. Moreover, the flat model's coefficient of friction is lower than the coefficient of friction of the groove models, with percentages of 0.38%, 4.63%, and 17.37%, respectively.

Graphical Abstract

Highlights

- The pressure distribution increased at 3mm groove width compared to 5mm and 8mm.

- The grooved models are lower than 0.5, 4.2, and 14.6% of the load capacity of the flat model.

- The flat model coefficient of friction is lower than the grooved models by 0.3,4.6, and 17.3%.

- The maximum load-carrying of flat and grooved models was in the film ratio (K) = 2–2.5.

Keywords

Main Subjects